Personal Protective Equipment (PPE) – Fact Sheet

What is Personal Protective Equipment (PPE)?

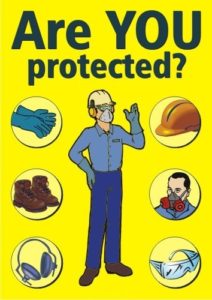

PPE is equipment worn by a worker to minimize exposure to specific hazards. Examples of PPE include respirators, gloves, aprons, fall protection, and full body suits, as well as head, eye and foot protection. Using PPE is only one element in a complete hazard control program that would use a variety of strategies to maintain a safe and healthy environment. PPE does not reduce the hazard itself nor does it guarantee permanent or total protection.

Are you properly protected?

Workers and employers can eliminate or control the prospect of occupational hazards. How? By knowing about possible hazards and by getting protection through use of personal protective equipment (PPE).

Identify and Assess Hazards

The first step is to identify and assess the hazards that come with a particular job or work process. You need to determine the source of the hazard nature of the hazard (physical, biological or chemical) duration of exposure to the hazard – long term versus short term exposure level of the hazard.

Control Hazards

Where a hazard is identified, try to control that hazard at the source or between the source and the worker. Before turning to PPE, consider the following eliminate the hazard through engineering controls at the source, this could mean having to modify or replace equipment substitute hazardous materials or substances with less or non-hazardous alternatives redesign the work process – e.g. modify sequence of tasks to improve safety isolate the hazardous agent – e.g. designated room or local ventilation develop administrative controls – e.g. limit the time exposed to the hazard.

Choosing and Using PPE

If engineering controls are neither feasible nor result in completely eliminating the hazard, PPE must be used. Criteria for choosing PPE should be that they provide adequate protection for the worker comply with applicable laws, regulations meet company standard not cause undue discomfort and doesn’t create new hazards.

Consider why and for how long the PPE is needed, such as for a short time due to a temporary process or in case of temporary breakdown of engineering controls for long term, regular use to compensate for lack of engineering control or inadequate control during handling of substances, clean-up of spills, repair of equipment to comply with law and regulations.

Also consider the nature and size of the hazard degree of protection the PPE will provide how easy the PPE is to use and how well the worker will accept using the PPE.

Proper fit is important

A proper fit ensures maximum effectiveness of the equipment, and that the equipment itself does not cause discomfort or pose a further hazard.

What are your PPE Responsibilities?

- Make sure you are educated and trained in how and when to fit and wear your PPE properly, and how to clean, maintain, store, and dispose of it, before you start work.

- Wear all PPE required for the job.

- Check that your PPE does not compromise your health and safety (for example, interfere with your breathing, vision, communication, or mobility.)

- Take care of your PPE – clean, maintain, and store it properly.

- Inspect you PPE for wear and tear and other damage before use.

- Make sure your PPE is repaired or replaced as necessary. Report any damage to your supervisor or employer.